Machine Maintenance

Industry news

2022-08-25 09:10:56

| No. | Name | Lubricator oil | |||

| 1 | Motor | Add lubricator oil per half year | |||

| 2 | Bearing | Add lubricator oil per month | |||

| 3 | Bearing | Add lubricator oil per month | |||

| 4 | Bearing | Add lubricator oil per month | |||

| 5 | Linear guide | Add lubricator oil per 12 hours | |||

| 6 | Linear guide | Add lubricator oil per 12 hours | |||

| 7 | Five machine valve | Clean per month | |||

| 8 | Vacuum filter/Blocked | Clean by and generator air gun(per day) | |||

| 9 | Linear guide | Add lubricator oil per 12 hours | |||

| 10 | Fisheye joint | Add lubricator oil per 12 hours | |||

| 11 | Pneumatic Component (two united) | When the water to 1/3 of cup,drain the water | |||

| 12 | Blade | Add light machine oil per 8 hours | |||

| 13 | Chain wheel | Add lubricator oil per month | |||

| 14 | Silencer | Clean per month | |||

| 15 | Bearing set | Add lubricator oil per 12month | |||

| 16 | Lengthen set bearing | Add lubricator oil per 12month | |||

| 17 | Straight bearing | Add lubricator oil per 12month | |||

| 18 | Set bearing | Add lubricator oil per 12month | |||

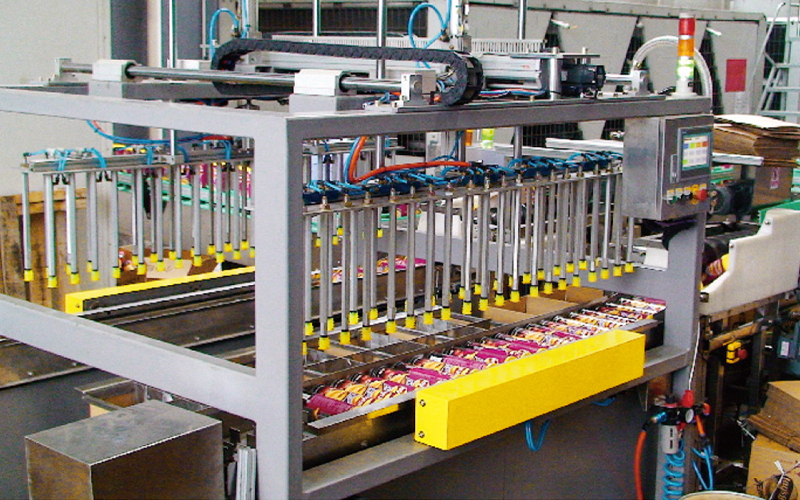

Automatic forming bottom sealer:

Pneumatic components: Firstly,notice the cleanness of air source.

So keep the air´s cleanness and supply enough air source in order to

ensure the components´ motions, meanwhile, set the pressure at 5-6kg/c㎡,

clean the shaft of cylinder frequently to prevent dust into the piston

which causes air leaking.

If you need to dismantle the maintenance parts, you must note the air pipe whether be folded when return them back. If it´s gas barrier, put it ok to avoid air choking.

Suction pad: keep cleanness of pad, avoid adhere the oil. Vacuum producer must be cleaned weekly. Must clean it frequently when cartons are dirty .

Serve units: check the water filter, look the water in the cup, if it´s too much, drain it to avoid the pneumatic components damaged. Suggestion: Draining the water once per day is probable.

Carton Sealer:

Serve units: Check the oil, please add oil which is used for pneumatic (transparent oil) when it´s not enough. Notice: Must not use other oil to avoid the loop of pneumatic choking.

Check the water filter, look the water in the cup, if it´s too much, drain it to avoid the pneumatic components damaged. Suggestion: Drain the water once per day is probable.

Blade: Add light machine oil per 8 hours.

Make the belt tighter a little probably after using the machine some days to make sure it´s not slip or damage the guide rail.